Centric Butterfly Valve

Working Principles

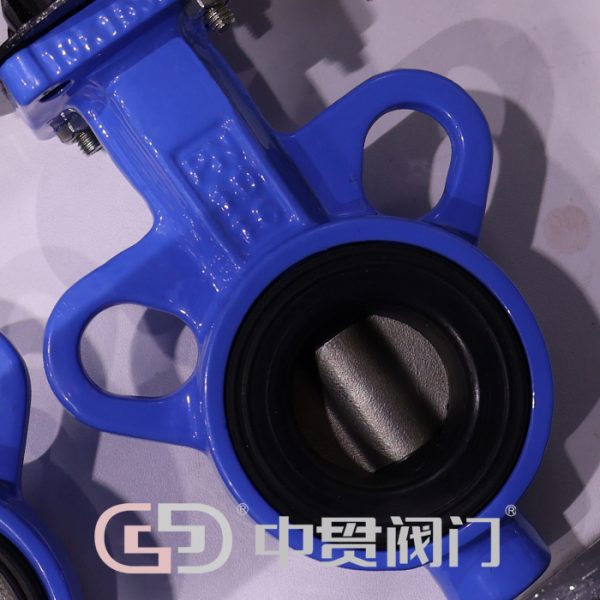

Centric butterfly valve operates on a quarter-turn principle, where the disc rotates 90 degrees to control the flow of fluid. The disc is positioned at the center of the pipe, allowing it to rotate freely within the valve body. When the valve is closed, the disc is perpendicular to the flow, blocking the passage of fluid. When the valve is open, the disc is parallel to the flow, allowing fluid to pass through with minimal obstruction.

The stem of the valve passes through the center of the disc, connecting it to the actuator. This design allows for precise control over the position of the disc, enabling smooth and efficient regulation of fluid flow. The seat, typically made from elastomers or rubber, is located within the valve body and provides a tight seal when the valve is closed.

Practical Applications

Centric butterfly valve is widely used in various industries due to their versatility and efficiency. Some common applications include:

- Water Treatment: Centric butterfly valves are used in water treatment plants to regulate the flow of water and other fluids.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, centric butterfly valves are used to control the flow of air and water.

- Industrial Processes: Centric butterfly valves are used in various industrial processes, such as chemical processing, pulp and paper manufacturing, and mining, where reliable flow control is essential.

Advantages

Centric butterfly valve offers several advantages over other types of valves, including:

- Simplicity: The simple design of centric butterfly valves makes them easy to install and operate.

- Cost-Effectiveness: Centric butterfly valves are relatively inexpensive compared to other types of valves, making them a cost-effective choice for many applications.

- Efficiency: The streamlined design of centric butterfly valves allows for high flow capacity with minimal pressure drop, ensuring efficient fluid control.

- Reliability: The resilient-seated design of centric butterfly valves ensures a reliable seal even under low-pressure conditions.

Maintenance Considerations

To ensure the optimal performance and longevity of centric butterfly valve, regular maintenance is essential. This includes:

- Inspecting the Valve: Regularly inspect the valve for signs of wear and tear, such as corrosion or damage to the disc or seat.

- Lubrication: Ensure that the valve is properly lubricated to prevent friction and ensure smooth operation.

- Replacing Seals: If the seals show signs of wear or damage, they should be replaced promptly to maintain a tight seal.

Conclusion

In conclusion, centric butterfly valve is essential components in fluid control systems, offering efficient and reliable performance in a wide range of applications. Their simple yet effective design, combined with their versatility and cost-effectiveness, makes them a popular choice for many industries. By understanding the working principles, design features, practical applications, advantages, and maintenance considerations of centric butterfly valve, you can make informed decisions regarding their use in your specific application.