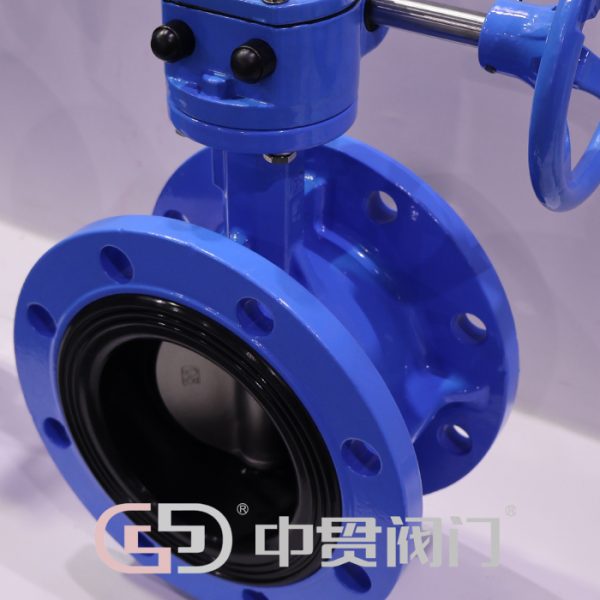

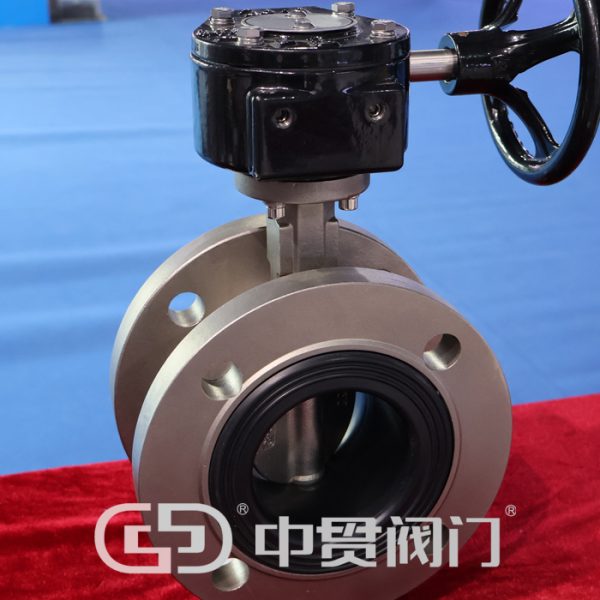

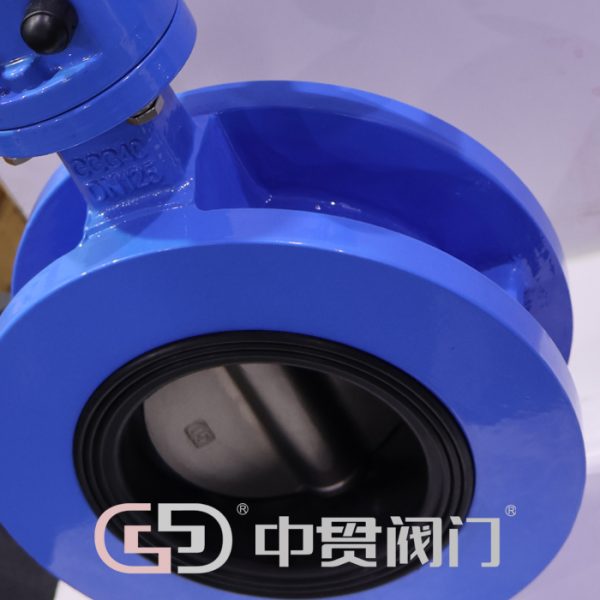

Flange Type Butterfly Valve

Flange Type Butterfly Valve are a crucial component in various industrial and commercial applications due to their efficient design and reliable performance. These valves are widely used in systems where the control of fluid flow is essential, including water treatment plants, chemical processing, oil and gas industries, and HVAC systems. This article will provide an in-depth understanding of flange butterfly valves, their construction, working principle, applications, and benefits.

Structural Features

- Positioning:

- The Flange type Butterfly Valve‘s centerline determines its precise location within the piping system.

- Proper positioning ensures optimal flow control and alignment with other components.

- Orientation:

- The orientation of the Flange Type Butterfly Valve’s centerline is crucial for its correct installation.

- Correct orientation minimizes stress on the valve and surrounding components, enhancing its longevity.

- Alignment:

- Proper alignment of the Flange Type Butterfly Valve’s centerline is essential for a leak-free seal.

- Misalignment can lead to leaks, inefficiencies, and potential safety hazards.

- Functionality:

- The Flange Type Butterfly Valve’s centerline plays a pivotal role in its operational effectiveness.

- Precise positioning, orientation, and alignment ensure smooth valve operation and efficient flow regulation.

- Maintenance:

- Regular maintenance of the Flange Concentric Butterfly Valve’s centerline is crucial for sustained performance.

- Proper alignment reduces wear and tear, extending the valve’s service life.

Dimension

| SIZE | DN | Φ D | Φ D1 | b (mm) | f1 | L | N-Φ d | C | Φ G | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | A-series | B-series | A-series | B-series | A-series | B-series | (mm) | (mm) | A-series | B-series | ||

| 2 | 50 | 150 | 120.7 | 17.5 | 2 | 108 | 4 – Φ 19 | F05 | 9 X 9 | ||||

| 2 1/2 | 65 | 180 | 139.7 | 20.7 | 2 | 112 | 4 – Φ 19 | F05 | 9 X 9 | ||||

| 3 | 80 | 190 | 152.4 | 22.3 | 2 | 114 | 4 – Φ 19 | F05 | 9 X 9 | ||||

| 4 | 100 | 230 | 190.5 | 22.3 | 2 | 127 | 8 – Φ 19 | F07 | 11 X 11 | ||||

| 5 | 125 | 255 | 215.9 | 22.3 | 2 | 140 | 8 – Φ 22 | F07 | 14 X 14 | ||||

| 6 | 150 | 280 | 241.3 | 23.9 | 2 | 140 | 8 – Φ 22 | F07 | 14 X 14 | ||||

| 8 | 200 | 345 | 298.5 | 27 | 2 | 152 | 8 – Φ 22 | F10 | 17 X 17 | ||||

| 10 | 250 | 405 | 362 | 28.6 | 2 | 165 | 12 – Φ 25 | F10 | 22 X 22 | ||||

| 12 | 300 | 485 | 431.8 | 30.2 | 2 | 178 | 12 – Φ 25 | F10 | 22 X 22 | ||||

| 14 | 350 | 535 | 476.3 | 35.4 | 2 | 190 | 12 – Φ 29 | F10 | 22 X 22 | ||||

| 16 | 400 | 595 | 539.8 | 37 | 2 | 216 | 16 – Φ 29 | F14 | |||||

| 18 | 450 | 635 | 577.9 | 40.1 | 2 | 222 | 16 – Φ 32 | F14 | |||||

| 20 | 500 | 700 | 635 | 43.3 | 2 | 229 | 20 – Φ 32 | F14 | |||||

| 24 | 600 | 815 | 749.3 | 48.1 | 2 | 267 | 20 – Φ 35 | F16 | |||||

| 28 | 700 | 925 | 835 | 863.6 | 795.3 | 69.9 | 44.5 | 2 | 292 | 28 – Φ 35 | 40 – Φ 22 | F25 | |

| 32 | 800 | 1060 | 940 | 977.9 | 900.1 | 79.4 | 46 | 2 | 318 | 28- Φ 41 | 48 – Φ 22 | F25 | |

| 36 | 900 | 1170 | 1055 | 1085.8 | 1009.6 | 88.9 | 52.5 | 2 | 330 | 32 – Φ 41 | 44 – Φ 25 | F25 | |

| 40 | 1000 | 1290 | 1175 | 1200.2 | 1120.8 | 88.9 | 56 | 2 | 410 | 36 – Φ 41 | 44 – Φ 29 | F25 | |

| 48 | 1200 | 1510 | 390 | 1422.4 | 1335.1 | 106.4 | 65.5 | 2 | 470 | 44 – Φ 41 | 44 – Φ 32 | F30 | |

MORE DETAILS OR REQUIREMENTS NEED TO BE CONFIRMED PLEASE DOWNLOAD THE CATALOG OR CONTACT US

Conclusion

Flange Type Butterfly Valve valves offer superior strength and reliability, making them an excellent choice for systems where high pressure and secure connections are critical. Their robust design and ease of installation make them a preferred option for various industrial applications, including chemical processing and water treatment.