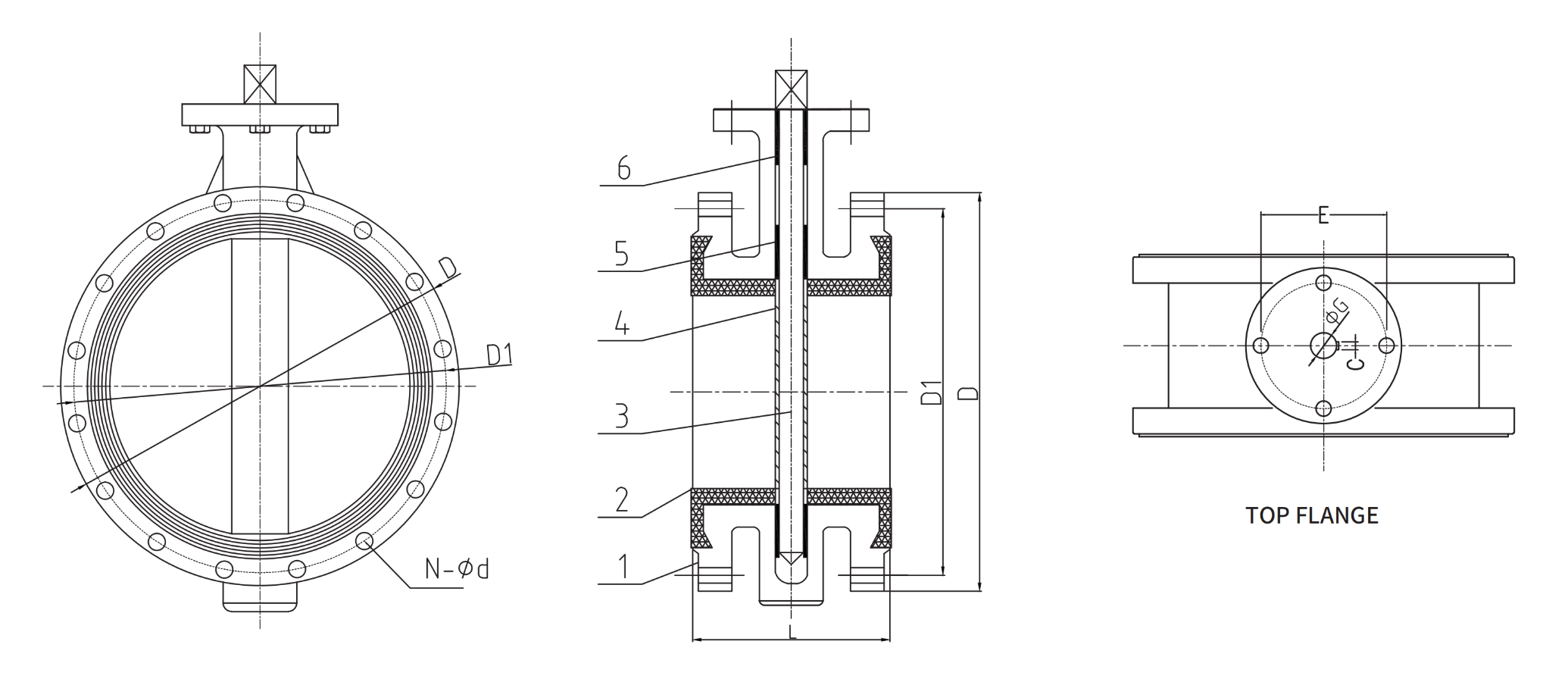

Handle Stainless steel PTFE seat concentric butterfly valve

The structural feature of a midline butterfly valve is that the valve stem axis, butterfly plate center, and body center are in the same position. Simple structure and convenient manufacturing. The common rubber lined butterfly valve belongs to this category. The disadvantage is that the butterfly plate and valve seat are always in a squeezing and scraping state, with a large resistance distance and fast wear. In order to overcome squeezing, scratching, and ensure sealing performance, the valve seat is basically made of elastic materials such as rubber or polytetrafluoroethylene. However, due to temperature limitations in the use of sealing materials, this is why people traditionally believe that butterfly valves are not resistant to high temperatures.

- Specifications:DN50-DN2200

- Pressure:PN10 / PN16 / ANSI150

- Structural length:GB/T12221; EN558; API609 DIN3202; ISO5752; BS5155

- Connecting flange:National standard: PN10, PN16 USA Standard: 150LB

- Working temperature:-50~150°C

- Driving method:Handle, turbine, electric, pneumatic, hydraulic

| DIMENSIONS | SIZE(mm) | |||||||

| SIZE | D 10/16</td=> |

D1 10/16 |

L | N-φd 10/16 |

C | E | φG | DN |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |