JIS 5K 10K Soft Back Replaceable Seat Marine Half Lugged Concentric Butterfly Valve

Main Parameters

- Specifications:DN50-DN2200

- Pressure:PN10 / PN16 / ANSI150

- Structural length:GB/T12221; EN558; API609 DIN3202; ISO5752; BS5155

- Connecting flange:National standard: PN10, PN16 USA Standard: 150LB

- Working temperature:-50~150°C

- Driving method:Handle, turbine, electric, pneumatic, hydraulic

Technical Data

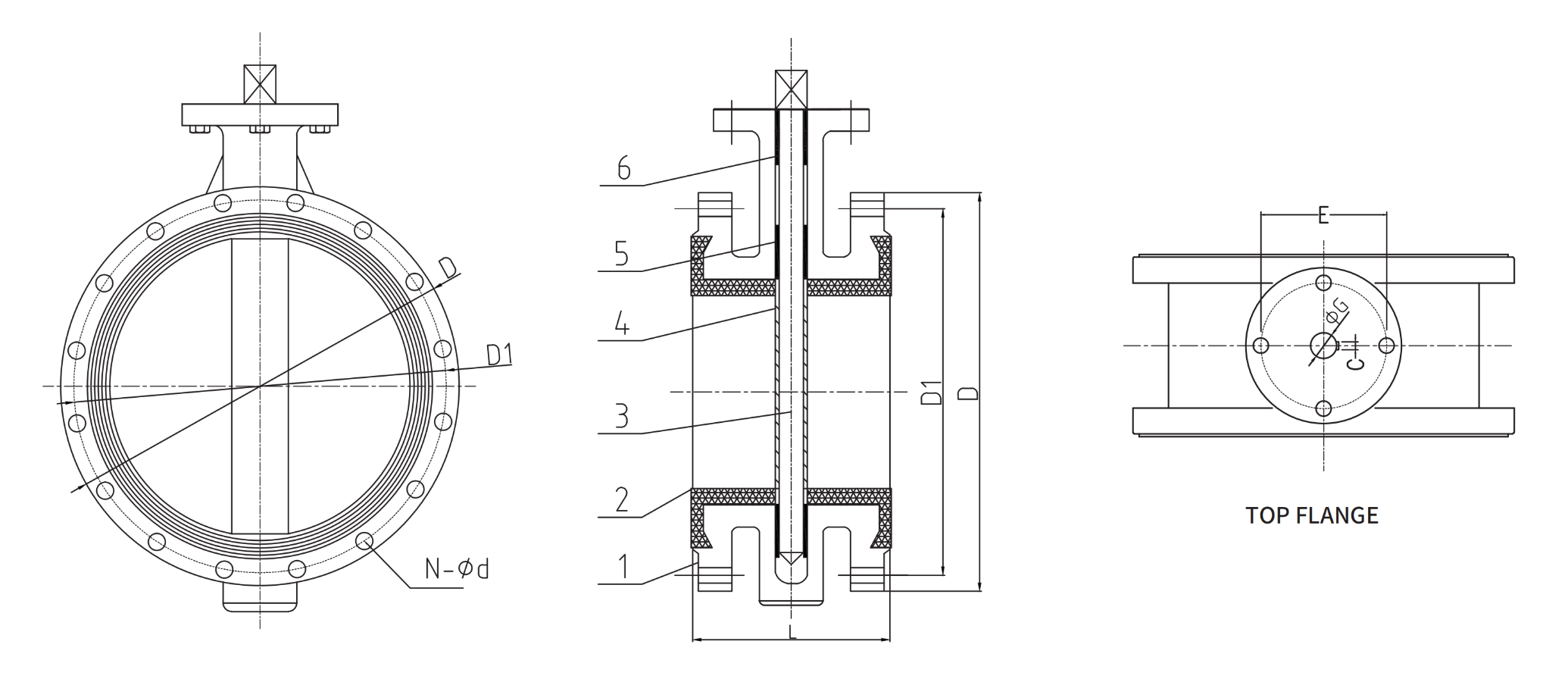

| DIMENSIONS | SIZE(mm) | |||||||

| SIZE | D 10/16</td=> |

D1 10/16 |

L | N-φd 10/16 |

C | E | φG | DN |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

| 2 | 165 | 125 | 108 | 4-φ 18 | 3 | 57.15 | 12.7 | 50 |

Simple description or definition of a lug type concentric butterfly valve

A lug type concentric butterfly valve is a crucial component in fluid control systems, known for its simplicity and effectiveness. This valve consists of a circular disc placed in the center of a pipe, which rotates around its axis to regulate the flow of fluids. The disc is mounted on a shaft, allowing it to pivot between an open and closed position. The “lug type” refers to the valve’s design, featuring threaded lugs on either side of the valve body. These lugs enable the valve to be bolted directly onto a pipeline, providing secure attachment without the need for additional support brackets. This design also facilitates easy installation and removal of the valve for maintenance or replacement. Concentric butterfly valves are aptly named because the center of the disc aligns with the center of the pipe bore when fully open, minimizing flow restrictions and pressure drops. This configuration ensures efficient flow control across a wide range of applications, including water treatment, HVAC systems, and industrial processes. Overall, the lug type concentric butterfly valve offers a reliable and cost-effective solution for controlling fluid flow in various industries, combining simplicity, durability, and performance.

Why is it called a lug type concentric butterfly valve

A “lug type concentric butterfly valve” gets its name from its design features:

Butterfly Valve: This type of valve derives its name from its resemblance to a butterfly, with a disc positioned in the center of the pipe, which rotates 90 degrees within the valve body to control flow.

Concentric: The term “concentric” indicates that the center of the disc (the butterfly) is aligned with the center of the pipe bore when the valve is fully open. This design helps minimize pressure drop across the valve.

Lug Type: “Lug” refers to the lugs or protrusions on the valve’s outer circumference. These lugs provide a method of attaching the valve to the pipe flanges using bolts, typically without the need for nuts on the opposite side. The lugs enable easier installation and removal of the valve without disrupting the pipeline.

So, when you put it all together, a “lug type concentric butterfly valve” is a type of valve with a disc centrally positioned within the pipe, operated by a quarter-turn rotation, and featuring lugs for easy installation and removal.

Design characteristics of lug type concentric butterfly valve

A lug type concentric butterfly valve typically shares several design characteristics, including:

Body Structure: The body of the valve is usually made of cast iron, ductile iron, carbon steel, stainless steel, or other materials suitable for the intended application. It typically features a compact, wafer-style design.

Butterfly Disc: The valve’s disc, which controls flow, is concentrically mounted within the body. This means the shaft is positioned at the center of the disc, allowing for uniform sealing and minimizing wear during operation.

Lug Mounting: Lug type valves have lugs (protruding ears) on the valve body, allowing the valve to be bolted between two flanges. This design makes installation and removal easier since the valve can be installed or removed from the pipeline without disturbing the adjacent pipes.

Sealing Mechanism: The sealing mechanism usually involves a resilient seat, such as EPDM, NBR, or PTFE, which ensures tight shut-off when the valve is closed and provides reliable sealing against leakage during operation.

Actuation: Lug type concentric butterfly valves can be operated manually or automatically using various actuation methods, including hand levers, gear operators, pneumatic actuators, or electric actuators. Actuation allows for remote operation and automation of the valve.

Bi-Directional Flow: These valves are often designed to allow flow in both directions, making them suitable for applications where the direction of flow may vary.

Pressure and Temperature Ratings: The design takes into account the pressure and temperature ratings required for the intended application, ensuring that the valve can safely and reliably handle the operating conditions.

Corrosion Resistance: Depending on the application, the valve may be coated with corrosion-resistant materials or lined with materials such as rubber or PTFE to protect against corrosion and abrasion.

Size Range: Lug type concentric butterfly valves are available in a wide range of sizes to accommodate different piping systems and flow requirements, from small diameters to large industrial applications.

Compliance Standards: These valves are designed and manufactured according to industry standards such as API, ANSI, ISO, or DIN, ensuring quality, performance, and compatibility with existing piping systems and equipment.

Overall, the design characteristics of lug type concentric butterfly valves prioritize ease of installation, reliable sealing, efficient flow control, and compatibility with various operating conditions and applications.

Types of Connection for Stem and disc of concentric Butterfly Valve

Splined Connection: Similar to the keyed connection, but instead of a key and slot, the stem and disc have interlocking splines. This provides a more secure connection, especially in high-pressure applications.

Precision double “D” disc to stem connection drives the disc without the need for screws or pins. The close tolerance, double “D” connection that drives the valve disc is an exclusive feature. Disassembly of the stem is just a matter of pulling the stem out of the disc.

Pin Connection: The stem and disc are connected using a pin that passes through both components. This connection method is simple and effective but may require more effort for disassembly.

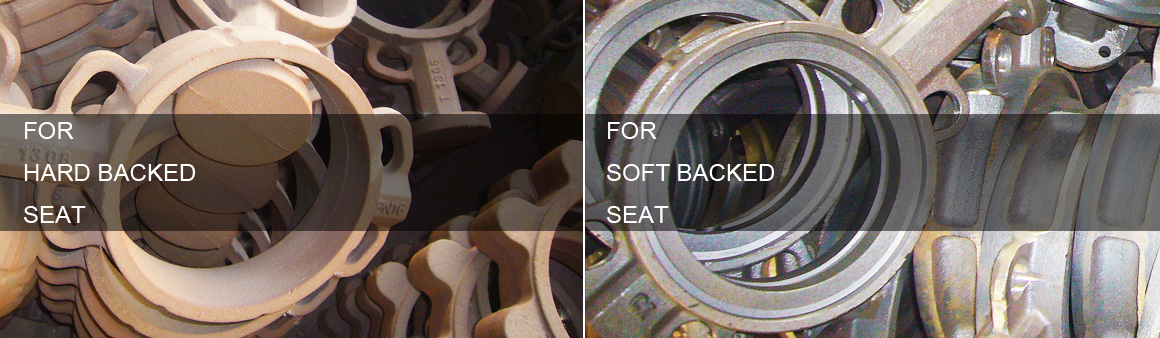

Design Structure Characteristics and Types of Valve Seat and Valve Body for lug type concentric Butterfly Valves

The tongue groove valve seat design can completely isolate the flowing medium from the body. This design is easy to install and facilitates the replacement of valve seats.

The material of the hard backrest valve seat is composed of the outer rubber wrapped on the inner hard backrest. Its installation method is to use a professional valve assembly platform to press the valve seat into the valve body through a machine. At the same time, the valve seat is also classified into ordinary type and water line type.

The overall material of the soft backrest valve seat is only composed of rubber, so it has high elasticity and is also called a backless valve seat. Its installation method is convenient for workers to repair, replace, and disassemble it later.

The rubber ring of the rubber lined butterfly valve is integrated with the valve body and hung on the valve body as a whole. It is produced in bulk by large equipment. Compared with traditional butterfly valves, this type of butterfly valve has the advantages of high temperature resistance, easy operation, no friction when opening and closing, good sealing performance and long service life. Therefore, it is widely used in engineering systems such as fire protection, buildings, food, papermaking, textile, medical, industrial water, urban sewage, gas, natural gas, liquefied petroleum gas, urban gas, cold and hot air, chemical smelting, and power generation. It is used to regulate and cut off the flow of various corrosive and non corrosive fluid media in pipelines that transport various corrosive and non corrosive fluid media.

Selection of Main Valve Body Materials and Internal Component Materials for lug type concentric Butterfly Valves

Selecting the materials for the main valve body and internal components of concentric butterfly valves depends on various factors including the type of fluid being handled, operating conditions (temperature and pressure), corrosion resistance requirements, and budget constraints. Here’s a general guideline:

Main Valve Body Materials:

Ductile Iron (DI): This is a common material for butterfly valve bodies due to its cost-effectiveness and good mechanical properties. It’s suitable for handling water, air, and non-corrosive fluids.

Cast Steel: For higher pressure applications or where better mechanical properties are required, cast steel valve bodies are preferred.

Stainless Steel: Particularly for corrosive environments, stainless steel (such as 316 or 304 grades) offers excellent corrosion resistance. It’s suitable for handling corrosive fluids like acids, chemicals, and seawater.

Carbon Steel: Provides good strength and is often used for moderate-pressure applications with non-corrosive fluids.

Internal Component Materials:

Disc (Butterfly):

Stainless Steel: Provides good corrosion resistance and strength. 316 or 304 stainless steel are common choices.

Aluminum Bronze: Offers high strength and corrosion resistance, particularly in seawater and corrosive environments.

Seat:

PTFE (Polytetrafluoroethylene): Commonly used due to its excellent chemical resistance and low friction properties.

EPDM (Ethylene Propylene Diene Monomer): Suitable for handling water and mild chemicals, providing good resilience and sealing properties.

Nitrile (Buna-N): Offers good resistance to oils, fuels, and hydrocarbons.

Shaft:

Stainless Steel: Provides good corrosion resistance and strength.

Carbon Steel: Suitable for non-corrosive environments and moderate-pressure applications.

Bearings:

Bronze or PTFE: Depending on the application, bronze or PTFE bearings can be used for low friction and smooth operation.

Other Considerations:

Temperature Resistance: Ensure that the materials selected can withstand the temperature range of the application without degradation.

Pressure Rating: Verify that the materials meet the pressure rating requirements of the system.

Compatibility: Confirm that the materials are compatible with the fluid being handled to avoid corrosion or chemical reactions.

Types of driving methods for lug type concentric butterfly valves

Concentric butterfly valves can be operated using various driving methods, each suited to different applications and operational requirements. Here are some common types:

Manual Operation: This involves a hand-operated lever or gear mechanism attached directly to the valve stem. Manual operation is simple and reliable, making it suitable for small-scale applications or situations where power sources are unavailable or impractical.

Electric Actuation: Electric actuators use an electric motor to drive the valve, providing precise control over the valve position. Electrically operated butterfly valves are commonly used in industrial applications where automation and remote control are required.

Pneumatic Actuation: Pneumatic actuators utilize compressed air to operate the valve. They are suitable for applications where electricity is not readily available or where there are concerns about sparking. Pneumatic actuators offer fast operation and can provide substantial force, making them suitable for larger valves or high-cycle applications.

Hydraulic Actuation: Hydraulic actuators use hydraulic fluid to drive the valve. They offer high force capabilities and precise control, making them suitable for large valves or applications where high pressure or high torque is required. Hydraulic actuators are often used in heavy-duty industrial applications.

Hydraulic Manual Override: Some butterfly valves feature a manual override mechanism that allows manual operation in case of power failure or for maintenance purposes. This is often achieved by incorporating a hydraulic hand pump or similar mechanism that can be used to operate the valve manually when needed.

Gear Operation: In some cases, large butterfly valves may be operated using a gear mechanism instead of directly by hand. Gear-operated valves provide mechanical advantage, allowing for easier operation of large valves or valves that require higher torque.

The main types of concentric butterfly valves

Concentric butterfly valves are a type of quarter-turn valve used to control the flow of fluids in pipes. They consist of a metal disk mounted on a rod, which rotates perpendicular to the flow of the fluid. The main types of concentric butterfly valves are:

Rubber Seated: In this type, the valve seat is typically made of resilient materials such as EPDM or Nitrile rubber. The disk is also often rubber-lined. Rubber seated valves are suitable for applications where tight shut-off is required and are commonly used in water treatment, HVAC systems, and general industrial applications.

PTFE Seated: PTFE (polytetrafluoroethylene) seated butterfly valves feature seats made of PTFE, which provides excellent chemical resistance and low friction. These valves are ideal for applications involving corrosive fluids and are commonly used in chemical processing, pharmaceutical, and food and beverage industries.

Each type of concentric butterfly valve has its advantages and limitations, and the selection depends on factors such as the fluid being handled, operating conditions, and required performance characteristics.

Application field of concentric butterfly valve

Concentric butterfly valves find application across various industries due to their versatility and effectiveness in controlling the flow of fluids. Here are some common fields where concentric butterfly valves are used:

Water Treatment Plants: They are widely used in water treatment facilities for regulating the flow of water, whether it’s for treatment, distribution, or wastewater management.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, these valves control the flow of air and water to maintain desired temperatures and air quality.

Chemical Processing: Concentric butterfly valves are utilized in chemical plants to regulate the flow of various chemicals in liquid or gas form during manufacturing processes.

Power Plants: They are employed in power generation facilities to control the flow of water, steam, or other fluids in boilers, cooling systems, and other processes.

Oil and Gas Industry: In refineries and petrochemical plants, these valves are used to regulate the flow of oil, gas, and other hydrocarbons throughout the production and refining processes.

Food and Beverage Industry: Concentric butterfly valves are used in food and beverage processing plants to control the flow of ingredients, water, and other fluids during manufacturing and packaging.

Marine and Shipbuilding: They are used in shipbuilding and marine applications for regulating the flow of water, fuel, and other fluids on ships and offshore platforms.

Pharmaceutical Industry: In pharmaceutical manufacturing, these valves help control the flow of liquids and gases during the production of medications and pharmaceutical products.

Pulp and Paper Industry: Concentric butterfly valves are employed in pulp and paper mills for regulating the flow of water, chemicals, and pulp slurries during various stages of paper production.

Mining and Minerals Processing: They are used in mining operations and minerals processing plants to control the flow of water, slurries, and chemicals in extraction and processing operations.

These are just a few examples, but the versatility of concentric butterfly valves makes them suitable for a wide range of applications where precise flow control is essential.

The operating principles of lug type concentric butterfly valve

A lug type concentric butterfly valve operates on a simple yet effective design principle, commonly used in various industries for fluid control. Here’s an overview of its operating principles:

Basic Design: The concentric butterfly valve consists of a circular disc mounted on a shaft, which rotates within the valve body to control the flow of fluids. The valve body is typically made of metal, such as cast iron, stainless steel, or aluminum.

Concentric Disc Design: The disc is positioned in the center of the pipe bore, hence the term “concentric.” This design ensures that the disc’s rotation causes minimal disturbance to the flow, resulting in lower pressure drop compared to other valve types.

Lug Type Connection: The valve body has lugs or protrusions on the outer circumference. These lugs are used to connect the valve securely between two flanges in the pipeline system. Bolts pass through the lugs and flanges to hold the valve in place.

Bi-Directional Sealing: The valve can typically provide a tight seal in both flow directions. When the valve is closed, the disc presses against the valve seat, preventing the flow of fluid. This bidirectional sealing capability makes the valve versatile and suitable for various applications.

Quarter-Turn Operation: The valve operates by rotating the disc a quarter-turn (90 degrees) between the fully open and fully closed positions. This quarter-turn operation allows for quick and easy control of fluid flow, making the valve suitable for applications where fast response times are required.

Manual or Actuated Operation: Lug type concentric butterfly valves can be operated manually using a hand lever or gear operator, or they can be actuated using pneumatic, hydraulic, or electric actuators for remote control and automation.

Maintenance and Service: These valves are relatively simple in design, making them easy to install, operate, and maintain. Routine maintenance may involve lubrication of the shaft and inspection of seals for wear and tear.

Application Flexibility: Lug type concentric butterfly valves find applications in various industries, including water and wastewater treatment, chemical processing, HVAC systems, power generation, and more. They are suitable for both on/off and throttling applications.

Overall, the operating principles of lug type concentric butterfly valves revolve around their straightforward design, reliable sealing capabilities, and ease of operation, making them a popular choice for fluid control in a wide range of industrial applications.