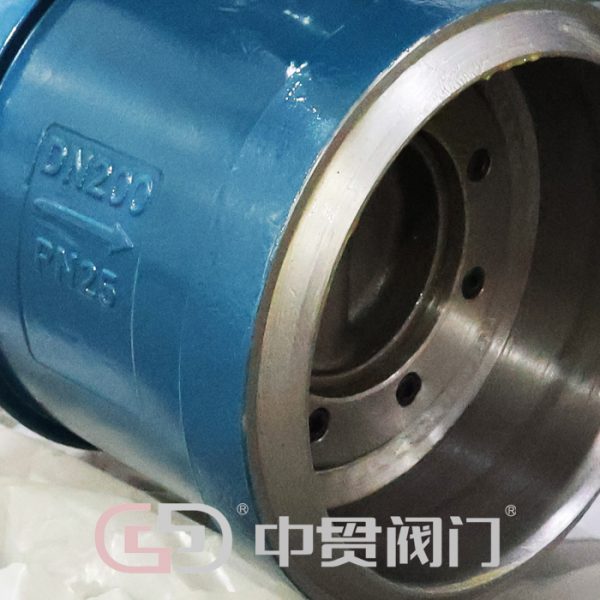

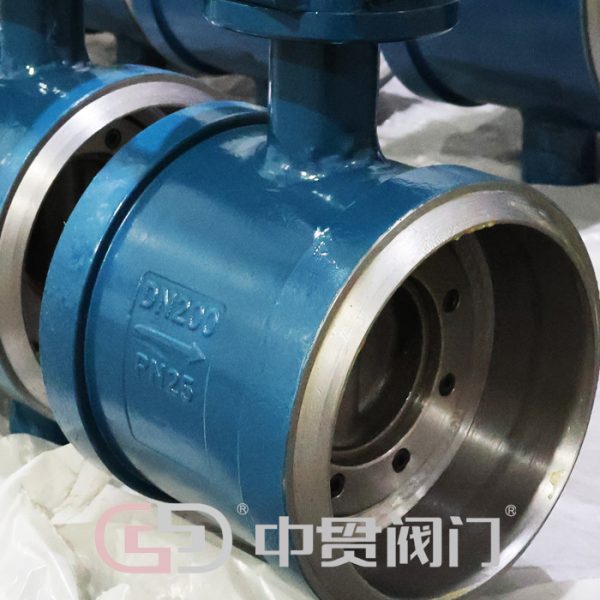

Manual Type Butt-Welded End Metal Sealed Triple Offset Butterfly Valve

Introduction to Triple Offset Butterfly Valves

The Triple Offset Butterfly Valve is a high-performance valve known for its durability and precision in critical industrial applications. Unlike conventional butterfly valves, the triple offset design provides a unique solution for handling high-pressure, high-temperature, and aggressive fluid systems, offering superior sealing and longevity. This article explores the structure, working principles, advantages, and common applications of the triple offset butterfly valve.

Key Components and Design Features

The metal-to-metal sealing in a triple offset butterfly valve allows it to operate effectively in environments where soft-seal valves would deteriorate. Some critical components include:

- Disc: Typically made of stainless steel or other corrosion-resistant alloys, it provides the necessary strength for handling aggressive media.

- Seat: Designed with precision to interact with the disc, the seat is also made of durable metals to ensure leak-tight performance.

- Body: The valve body can be constructed from various materials, such as carbon steel, stainless steel, or duplex alloys, depending on the application requirements.

The valve’s butt-welded or flanged end connections make it suitable for integration into pipelines requiring high-strength sealing and minimal leakage.

How Does the Triple Offset Design Work?

The triple offset design functions by ensuring that the disc only contacts the seat at the final moment of closure, eliminating any friction during the operation. This cam-action movement ensures that the disc moves in and out of the seat with minimal wear, which is critical in maintaining the integrity of the valve under repeated cycles.

This design is particularly useful in systems where high pressure and temperature variances can cause standard valves to deform or fail. The triple offset design prevents galling, warping, and thermal damage to the valve components.

Advantages of Triple Offset Butterfly Valves

The triple offset butterfly valve offers numerous advantages, especially for industries requiring robust, high-performance valves:

- Zero leakage: The metal-to-metal sealing provides bubble-tight closure, even under extreme conditions.

- High durability: The frictionless operation extends the valve’s life, minimizing wear and tear.

- Versatility: It can handle a wide range of fluids, including gases, steam, corrosive chemicals, and abrasive slurries.

- Temperature and pressure resistance: Suitable for high-temperature applications up to 800°C and high pressures, making it ideal for demanding industries.

- Bidirectional flow: This valve can control flow in both directions, providing operational flexibility.

The Advantage of But-Weld Connection

1. Higher Strength and Pressure Resistance

Butt-weld connections provide a very strong joint because the weld can achieve strength equal to or greater than that of the base material. This makes the connection highly reliable for handling high pressure and temperature applications.

2. Smooth Flow and Reduced Turbulence

The smooth interior surface of a butt-weld joint reduces fluid resistance and turbulence inside the pipeline. This results in improved flow efficiency and minimizes the risk of erosion and corrosion caused by turbulent flow.

3. Leak-Proof Connection

Due to the nature of the welding process, butt-weld joints offer a tight, leak-proof seal. This is particularly important in applications that involve hazardous or high-pressure fluids, where even small leaks can be costly or dangerous.

4. No Need for Additional Seals or Gaskets

Unlike flanged connections, butt-weld connections do not require additional seals or gaskets, which simplifies installation and reduces maintenance needs.

5. Space-Saving

Butt-weld connections are compact and take up less space compared to other connection methods like flanged or threaded joints. This is beneficial in environments where space is limited.

6. Long-Term Durability

Butt-welded joints are extremely durable and can withstand long-term use under harsh conditions. The absence of additional components like gaskets means fewer failure points, ensuring a longer service life.

7. Cost Efficiency Over Time

While the initial installation of butt-weld connections may require skilled labor, the long-term cost benefits include fewer maintenance needs, lower risk of leaks, and increased durability, making it a cost-efficient solution in the long run.

These benefits make butt-weld connections ideal for critical applications in industries such as oil and gas, chemical processing, and power generation, where safety, durability, and performance are key.

Conclusion

The triple offset butterfly valve is a superior choice for industries that require reliable, durable, and high-performance valves. Its innovative design ensures zero leakage, extended service life, and the ability to handle extreme pressure and temperature conditions. With its metal-to-metal seal and frictionless operation, it has become a vital component in a wide range of industrial applications, from oil and gas to power generation and chemical processing. For businesses looking to improve efficiency and reduce maintenance costs, the triple offset butterfly valve offers a dependable and long-lasting solution.