Resilient Seated Butterfly Valve

What is a Resilient Seated Butterfly Valve?

A resilient seated butterfly valve is a type of quarter-turn valve that uses a disc as the closure mechanism. The term “butterfly” in the name is derived from the shape of the disc, which resembles a butterfly’s wings. The resilient seat, made from materials such as rubber or elastomers, provides a soft, flexible sealing surface that ensures a tight shutoff.

Why "Butterfly Valve"?

The term “butterfly valve” comes from the shape and motion of the valve disc, which pivots on a central axis like the wings of a butterfly. When the valve is open, the disc is turned parallel to the flow of the fluid, allowing it to pass through with minimal resistance. When closed, the disc is turned perpendicular to the flow, effectively blocking the passage. This simple yet effective mechanism allows for quick and efficient fluid control.

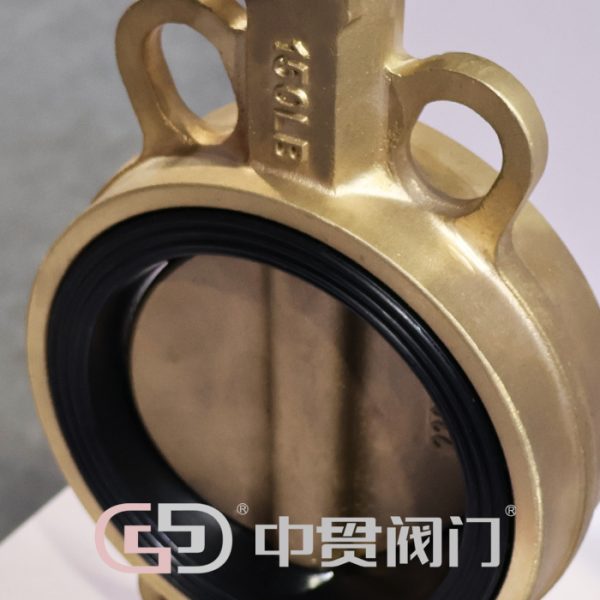

Anatomy of a Resilient Seated Butterfly Valve

- Valve Body: The main casing that houses the internal components of the valve. It is typically made from materials like cast iron, ductile iron, stainless steel, or PVC, depending on the application and the type of fluid being handled.

- Disc: The rotating element that controls the flow of fluid through the valve. The disc can be made from a variety of materials, including stainless steel, aluminum bronze, or coated with protective materials to enhance durability and corrosion resistance.

- Resilient Seat: The soft, flexible sealing element that lines the interior of the valve body where the disc makes contact. It is usually made from rubber or elastomers, providing a tight seal and accommodating minor misalignments and wear.

- Stem: The shaft that connects the actuator to the disc, enabling the opening and closing motion. The stem can be manually operated via a handle or automated using actuators.

- Actuator: The mechanism that controls the movement of the stem and disc. Actuators can be manual (lever or gear-operated) or automatic (electric, pneumatic, or hydraulic).

Working Principles of Resilient Seated Butterfly Valves

- Resilient seated butterfly valves operate on a simple yet effective quarter-turn mechanism. Here’s a step-by-step explanation of how they work:

- Opening the Valve: When the actuator is engaged, it rotates the stem and disc 90 degrees, aligning the disc parallel to the flow of the fluid. This position allows fluid to pass through the valve with minimal resistance.

- Closing the Valve: When the actuator is turned in the opposite direction, it rotates the disc back to its original position, perpendicular to the flow. The disc makes contact with the resilient seat, compressing it slightly to create a tight seal, preventing any fluid from passing through.

- Throttling: Resilient seated butterfly valves can also be used for throttling, or regulating the flow of fluid. By adjusting the position of the disc between fully open and fully closed, the flow rate can be controlled precisely.

Advantages of Resilient Seated Butterfly Valves

- Tight Seal: The resilient seat ensures a bubble-tight seal, preventing any leakage and maintaining the integrity of the fluid system.

- Durability: The flexible nature of the resilient seat accommodates minor misalignments and wear, prolonging the valve’s service life.

- Cost-Effective: Resilient seated butterfly valves are generally more affordable than other types of valves, both in terms of initial cost and maintenance.

- Ease of Operation: The quarter-turn mechanism allows for quick and easy operation, reducing the time and effort required to control fluid flow.

- Versatility: These valves can handle a wide range of fluids, including water, air, gases, and various chemicals, making them suitable for numerous applications.

Applications of Resilient Seated Butterfly Valves

- Water Treatment: These valves are extensively used in water treatment plants for controlling the flow of water and chemicals.

- HVAC Systems: In heating, ventilation, and air conditioning systems, resilient seated butterfly valves are used to regulate air and water flow.

- Chemical Processing: The chemical resistance of the resilient seat materials makes these valves suitable for handling a wide range of chemicals in processing plants.

- Food and Beverage: The hygienic properties of certain resilient seat materials, like PTFE and silicone, make them ideal for use in food and beverage processing.

- Pulp and Paper: These valves are used in the pulp and paper industry for regulating the flow of various chemicals and water during the manufacturing process.

Conclusion

Resilient seated butterfly valves are an essential component in modern fluid control systems, offering reliable sealing, ease of operation, and versatility across various applications. Understanding the different materials used for the resilient seats and their specific properties can help in selecting the right valve for your needs. By ensuring proper installation and regular maintenance, these valves can provide long-lasting performance and contribute to the efficiency and reliability of your fluid control system.