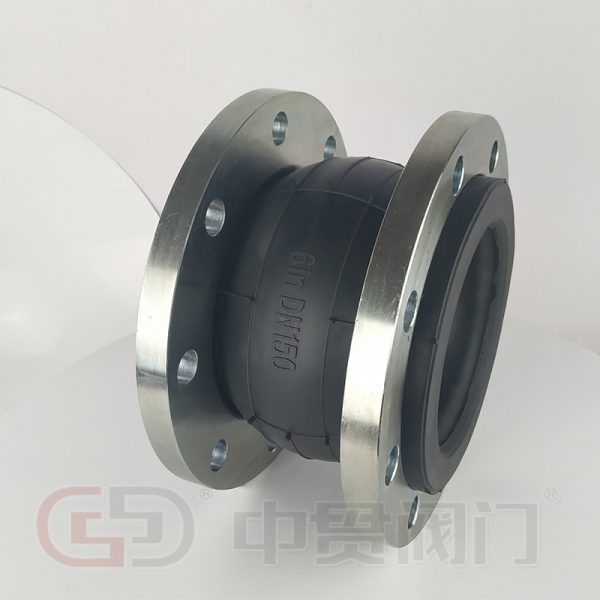

Rubber Joint

Functions of Rubber Joints

Rubber joints are primarily used to connect different pipes or equipment within a piping system, serving several key functions:

1. Vibration Damping: The elastic properties of rubber effectively absorb vibrations and shocks generated by equipment operation, protecting valves and the piping system.

2. Displacement Compensation: Rubber joints can flexibly adjust to displacements caused by temperature changes or ground settling, maintaining the sealing and integrity of the piping system.

3. Leak Prevention: High-quality rubber joints provide excellent sealing performance, effectively preventing fluid leakage and ensuring system safety and stability.

Advantages of Rubber Joints in Valves

1. Enhanced System Stability: The vibration-damping characteristics of rubber joints effectively reduce pipe system vibrations, minimizing equipment wear and improving overall stability.

2. Extended Equipment Lifespan: By buffering and compensating for displacements, rubber joints can lower the stress on pipes and valves, extending their service life.

3. Easy Maintenance: Rubber joints are relatively simple to install and replace, reducing maintenance time and costs, and enhancing overall efficiency.