What is Difference between Concentric and High Performance

An Overview of Butterfly Valves

This article will introduce concentric, Double-offset, and triple offset at first, then explain the difference among them.

l CONCENTRIC

According to the seat materials, Concentric butterfly valve can be divided into Resilient Seated and Polymer-Lined (PTFE-lined and PFA-lined valves).

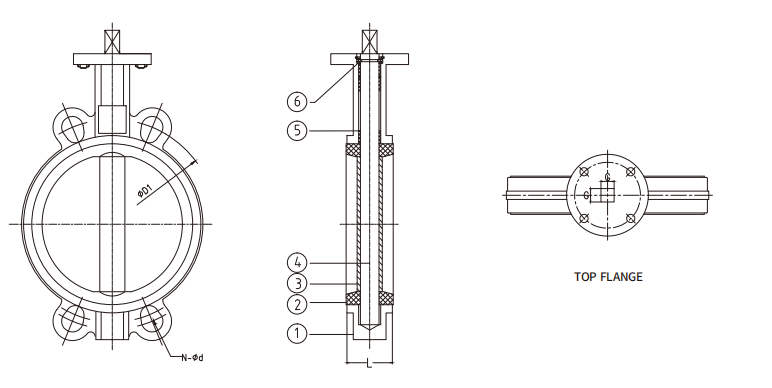

Resilient seated valves are designed with the disc positioned concentrically within the pipeline, ensuring consistent alignment. This valve configuration adopts a position-seated approach, maintaining continuous interference between the disc and the seat. Ratings for resilient seated valves typically adhere to cold working pressure (CWP) standards rather than traditional class ratings, although they typically fall within the range of ASME Class 125 and Class 150 flanges. Due to their design, resilient seated valves are frequently engineered below ASME pressure class ratings, making them a cost-effective choice for applications involving lower pressures.

Lined butterfly valves are also concentric with the pipeline and designed to be utilized with harsh chemical media: These polymer-lined products offer longer life in media with higher levels of acids.

l High Performance

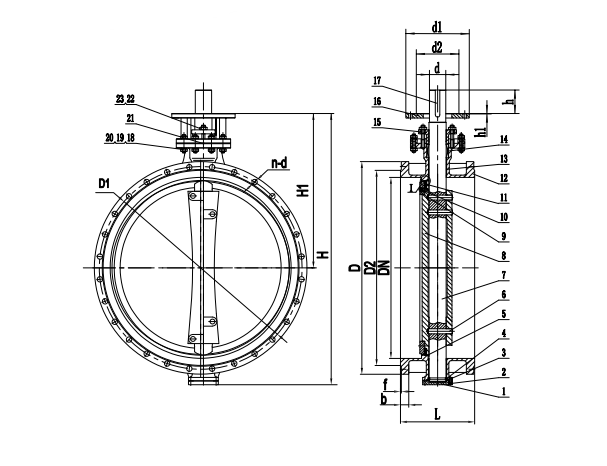

Triple offset valves, while sharing the first and second offset features with high-performance butterfly valves, introduce an additional third offset, employing inclined conical surfaces for seating. This third offset allows the sealing element, or seal ring, to engage with the seating surface only during the final degree of closing, subsequently disengaging upon opening. This design minimizes friction between the sealing components. Inherently fire-safe, triple offset valves are suitable for pressure classes ranging from Class 150 to Class 1500. Their versatile metal-to-metal sealing enables operation across a wide temperature range, from -320°F to 1,500°F, in various configurations.

The Difference among Them

| Description | Concentric | Double | Triple |

| Cost | Lowest | Moderate | Highest |

| Class Rating | 150 | 600 | 600 |

| Seat Friction | High | Low | Lowest |

| Seat Lifetime | Moderate | Long | Very Long |

| Bubble tight shut-Off | YES | YES | YES |

| Fluid Services | Clean | Clean | Clean to dirty |

| Pressure Drop | Lowest | Highest | Highest |

Conclusion

Butterfly valves offer a unique value proposition based on their weight, footprint, and cost effectiveness. They provide a variety of options from seat material, sealing designs, and range of temperature and pressure ratings. Butterfly valves offer one of the largest valve markets behind ball and gate valves. They continue to grow based on the flexibility of automation, lower torque and improved fugitive emissions performance compared to linear valves.