What is Water Hammer and How to Prevent or Fix

The Definition

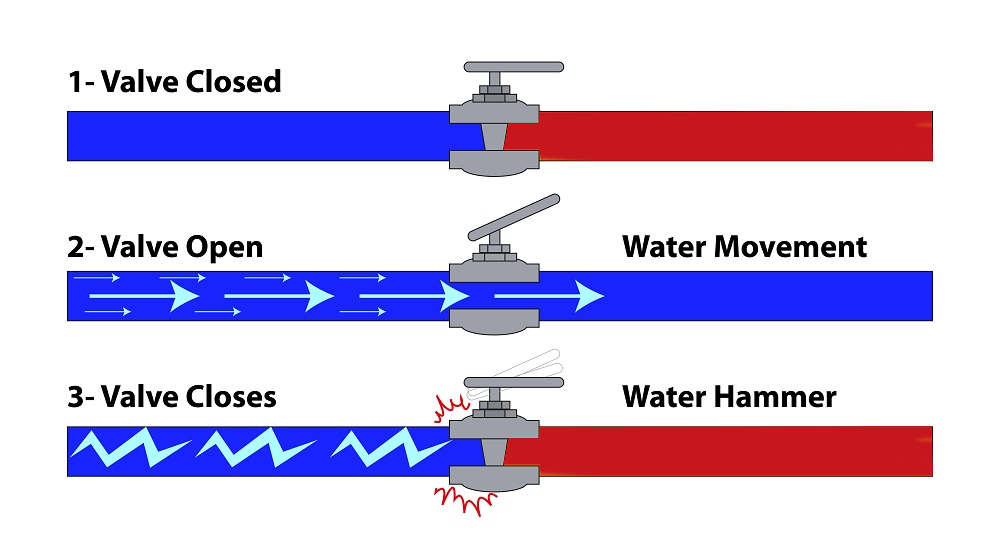

water hammer is a specific noise that’s caused by the sudden pressure to stop the flow of quick-moving water. When modern plumbing is installed correctly and maintained, the pipes have air chambers inside that help soften the sudden stop of water flow and eliminate the sound of water hammer.

How Does it occur?

Water hammer occurs when water flowing through a pipe suddenly changes direction. This happens because water doesn’t squish like air does, so when it has to stop suddenly, it creates a big pressure spike. This spike travels through the pipe like a mini explosion, looking for a way to calm down. It’s like when a speeding car crashes into a wall—the impact is related to how fast the car was going and how much stuff it’s carrying.

The methods of reduce or prevent water hammer.

- Draining Your Plumbing System: Step 1. Shut off the main water valve. Step 2. drain water from the lowest outlet. Step 3. Turn the main water valve back on and listen to see if the problem is fixed.

- Installing Water Hammer Arrestors.

- Tightening Loose Pipe Straps and Adding Insulation.

- Proper education and training of personnel on the dangers of water hammer and how to mitigate them through proper opening and closing of valves.

- Use start-up and shut-down procedures for pumps that reduce the possibility of creating water hammer conditions.

- Reduce the velocity of the liquid in the pipe. To keep water, hammer low, some references recommend keeping the flow velocity at or below 5 ft./s.

- Use slow-closing valves. Anything with a wheel, like a gate valve, is generally considered slow closing. Valves with handles, like butterfly valves or ball valves, are considered fast closing.

- Use pipe with a higher-pressure rating. For example, DR 26 HDPE pipe is rated for 65 psi, whereas DR 11 HDPE is rated for 160 psi.

- Air valves are often used to remediate low pressures at high points in the pipeline by admitting air into the line to reduce the possibility of partial vacuum and possible pipe collapse.

- Install pressure relief valves to prevent excessive pressure in the pipe.

- Use air chambers, surge vessels, accumulators or expansion tanks that are partially filled with air or gas and cushion possible shock.

Conclusion

To avoid or reduce the impact of water hammer in piping systems, it’s crucial to design pipeline valve actuation systems properly. Valves, which redirect the flow of fluid, affect how fast the fluid moves inside the pipe. Sometimes, valves need to change flow direction rapidly, but doing so too quickly can create high pressure peaks and waves. Implementing a variable-speed system for valve operation, along with thorough analysis of fluid movement and considering potential increases in flow when sizing piping systems, offers a practical solution to address water hammer challenges in pipeline valve operations.